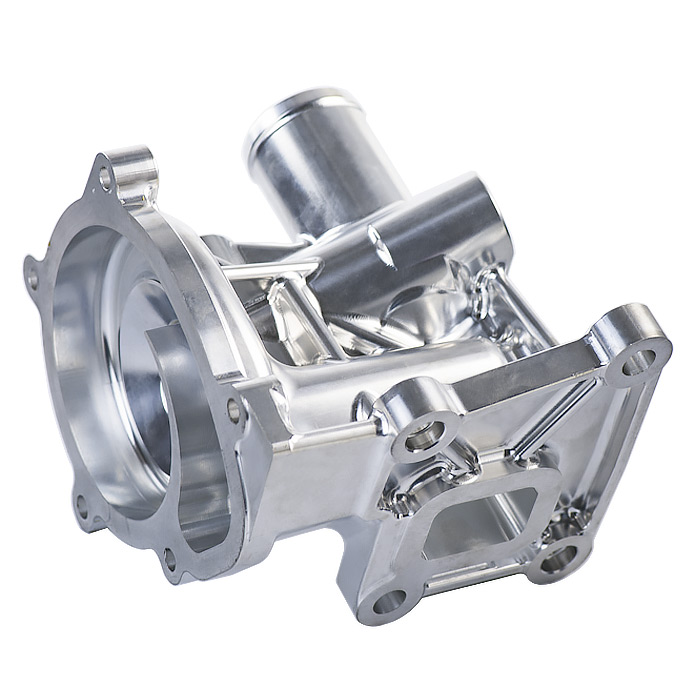

How to correctly use molds in aluminum die-casting process

Release time:25-02-2021

How to correctly use molds in aluminum die-casting process

Although the aluminum die-casting process has the characteristics of convenient use and relatively high yield, many people often ignore the protection of the mold during the die-casting process, or do not know how to use the mold correctly. The following is the mold for the aluminum die-casting process. From the following points, we will introduce in detail.

1. Stable cooling is needed in time

The aluminum die-casting process mold needs to be cooled by a cold water system, which can not only extend its service life but also increase the output. In actual operation, some operators have appeared in order to save trouble, and they do not connect the cold water pipe for cooling, and even some In order to save money, the company does not need cooling water for cooling when customizing molds. Experts pointed out that no matter how good the mold is, there are certain limits. If the temperature is too high, it may cause cracks in the film core or premature cracks. The final product is prone to deformation, mucous membrane, etc., and the production speed and quality of the product cannot be guaranteed.

2. It needs to be warmed up in time

The mold needs to be preheated before used to avoid cracks. At the same time, if the mold is equipped with neutron control, it must be ensured to avoid the signal line joint between the die casting machine and the mold.

The above are the issues that need to be paid attention to in the aluminum die-casting process. If it is not handled well, the automatic shutdown will cause a delay in sales and production time, and it may cause signal disorder, damage the mold, and cause unnecessary damage. It is recommended that the operator must not save trouble when using it, and must operate step by step.

-

Related Reading

-

How to use die correctly in aluminum die casting process

2021-01-25

-

Analysis of advantages and disadvantages of die casting

2021-01-25

-

CNC machining high precision aluminum parts and die casting aluminum parts

2021-02-01

-

Points for attention in machining OEM aluminum CNC parts

2021-02-01