-

plastic injection molding parts

plastic injection molding partsMaterial Available:PC,PET,PEEK,NYLON,ABS,TEFLON etc.

Tolerance:0.1mm-0.01mm-0.001mm

MOQ:100pcs

Surface finishes:Painting,power coating,nickel plating etc.

plastic injection machine partsMaterial Available:PC,PET,PEEK,NYLON,ABS,TEFLON etc.

Tolerance:0.1mm-0.01mm-0.001mm

MOQ:100pcs

Surface finishes:Painting,power coating,nickel plating etc.

Plastic injection parts

Plastic injection partsMaterial Available:PC,PET,PEEK,NYLON,ABS,TEFLON etc.

Tolerance:0.1mm-0.01mm-0.001mm

MOQ:100pcs

Surface finishes:Painting,power coating,nickel plating etc.

Injection molding products

Injection molding productsMaterial Available:PC,PET,PEEK,NYLON,ABS,TEFLON etc.

Tolerance:0.1mm-0.01mm-0.001mm

MOQ:100pcs

Surface finishes:Painting,power coating,nickel plating etc.

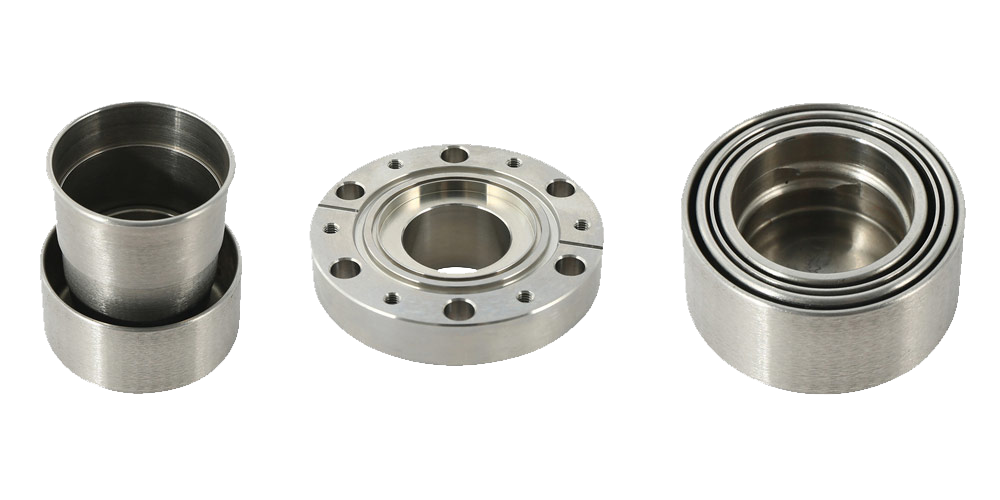

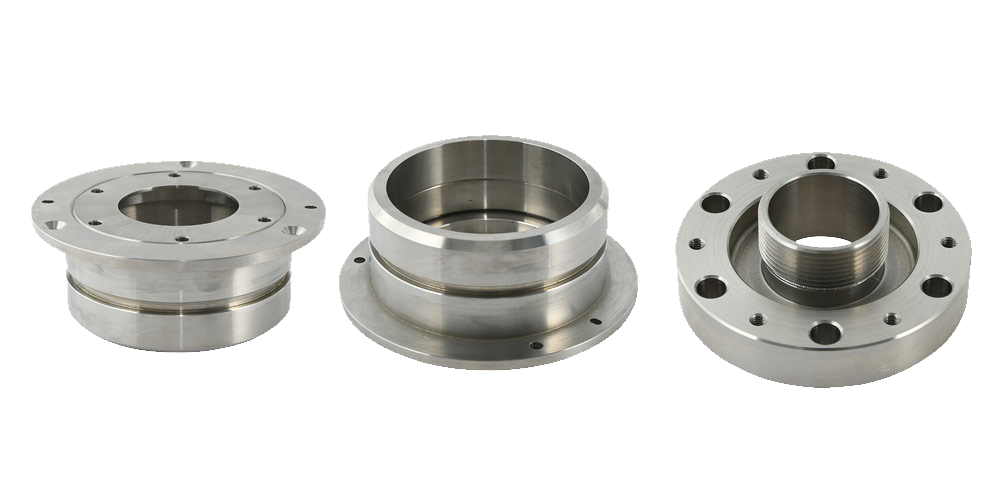

982C1379

982C1379Processing Technic : CNC stamping,CNC milling,EDM,Punching,Drilling, Broaching ect.

Material Available: Aluminum/Stainless steel/Brass/Steel

die-casting-2

die-casting-2Processing Technic:Die casting

Tolerance:0.1mm-0.01mm-0.001mm

MOQ:1000pcs

Material Available:Aluminum ,Brass,Bronze,Zinc etc.

Packing:Poly bag,Carton,as per customer's requirement

CNC Turning Parts Service in China

The application of CNC turning parts service not only brings revolutionary changes to the traditional manufacturing industry, making the manufacturing industry a symbol of industrialization, but also with the continuous development of technology and the expansion of application fields. CNC turning parts service has been widely used in modern manufacturing industry, and the performance of CNC machine tools of CNC turning parts service is unmatched by ordinary machine tools. The following is a brief introduction to the characteristics of CNC machine tools for CNC turning parts service:

1. the structural characteristics of CNC machine tools from the perspective of CNC turning parts service

(1) The transmission chain of the CNC machine tool is short. Compared with ordinary machine tools, the spindle drive is no longer a sub-mechanism of motor-belt-gear speed change, but adopts horizontal and vertical feed, and the decibel is two servo motors. The drive motion is accomplished without the use of shifting gears and clutch transmission components, so the drive chain of the CNC machine tool is very short.

(2) CNC turning parts service has high rigidity. In order to match the high precision of the CNC system, the rigidity of the CNC machine tool is particularly high. This is mainly for the use of high-precision machining requirements, which is unmatched by ordinary machine tools.

(3) The CNC turning parts of CNC machine tools are lightly dragged, and the movement of the tool holder adopts a ball screw, the friction force is very small, and the movement is very convenient. There are special bearings to support both ends of the screw. The pressure of CNC machine tools is greater than that of ordinary bearings. The lubrication part is lubricated by automatic oil mist lubrication of CNC machine tools. These measures make the movement of CNC machine tools very convenient.

2. What are the characteristics of CNC turning parts service CNC machine tool processing

(1) CNC turning parts service is highly flexible

Part machining on CNC Turned Parts Service is largely dependent on the machining program. There is no need to manufacture and replace many dies and fixtures, and there is no need to readjust the machine tool frequently. Therefore, CNC machine tools are suitable for occasions where processing parts are frequently replaced, that is, for the production of single-piece and small-batch products and the development of new products, thereby shortening the production preparation cycle and saving a lot of process equipment costs.

(2) CNC turning parts service with high machining accuracy

CNC Turned Parts Service CNC machines are controlled in the form of digital signals. Each time the numerical control device outputs a pulse signal, the moving parts of the machine tool move one pulse equivalent, and the average error of the backlash and pitch of the machine tool feed drive chain can be compensated by the curvature of the numerical control device, so the positioning accuracy of the numerical control machine tool is high.

(3) The machining quality of CNC turning parts is stable and reliable

Machining the same batch of parts, on the same machine tool, under the same processing conditions, using the same tool and processing program, the cutting path of the tool is exactly the same, the consistency of the parts is good, and the quality is good and stable.

(4) High productivity of CNC turning parts service

CNC turning parts service CNC machine tools can effectively reduce the processing time and auxiliary time of parts. The spindle sound speed and feed speed range of CNC machine tools are large, so that the machine tool can perform powerful cutting with a large amount of cutting. CNC machine tools are entering the era of high-speed machining. The fast moving positioning and high-speed cutting of the moving parts of the CNC machine tool greatly improve the production efficiency. In addition, it can be used in conjunction with the tool magazine of the machining center to realize continuous processing of multiple processes on one machine tool, reducing the turnaround time between semi-finished products and improving production efficiency.

(5) Improve working conditions

CNC turning parts service CNC machine tools are adjusted before processing, enter the program and start, and the machine tool can automatically and continuously process until the end of processing. What the operator has to do is program input, editing, parts loading and unloading, tool preparation, processing status observation, parts inspection, etc. The labor intensity is greatly reduced, and the labor of machine tool operators tends to be intellectual labor. In addition, machine tools are generally modular, which is clean and safe.

(6) Utilize production management modernization

The machining of CNC turning parts service can accurately estimate the machining time in advance, the tools and fixtures used are standardized and modernized, and it is easy to standardize the machining information. It has been organically combined with computer-aided design and manufacturing. It is the foundation of modern integrated manufacturing technology.

Cnc Precision Hardware Processing Technology

The CNC precision hardware processing technology has been extensively used in various industries because it offers high-precision performance and achieves the desired results quickly. The technology is also versatile, allowing for a wide variety of applications.

CNC precision hardware processing technology is becoming more and more popular as it offers several advantages over traditional manufacturing methods. First, CNC precision hardware processing technology is faster and easier to use, making it a better option for small batch production. Second, CNC precision hardware processing technology produces consistent products, which eliminates the need for multiple testing and quality control steps. Third, CNC precision hardware processing technology is less expensive than traditional manufacturing methods, making it a good choice for high-volume production.

Boyang CNC turning parts service

Boyang focus on producing high-quality products with complete specifications. When designing and developing new products according to customer needs, we strictly control quality standards while controlling production costs.

You can follow the link to see our facebook homepage.

Click on the link to go to our LinkedIn homepage.

You can also click the link below to enter our YouTube homepage to view.