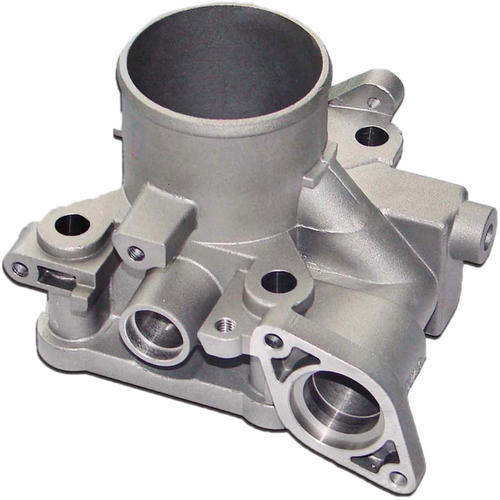

Professional OEM for high-precision CNC machining parts

Release time:04-01-2021

CNC machining, also known as numerical control machining, is controlled by computer through programming. CNC machining has the advantages of stable quality, high precision and high efficiency. Professional OEM, for high precision CNC machining parts, mainly includes the following three processes.

1. Centralized sorting of cutting tools

Take the tool used as the division of the process, use the same tool to process all the parts that can be completed, and then use the second tool, the third tool, the fourth tool to complete other parts, so as to reduce unnecessary tool error and positioning error.

2. Through the process arrangement of processing parts

According to the structural characteristics of the processing parts, the processing parts are classified, and then processed step by step, such as first processing the plane, then processing the positioning surface, and finally processing the hole.

3. The rough or fine CNC machining process is used to classify the machining parts

In general, rough machining and finish machining should be carried out separately to distinguish the processing program.

To sum up, professional OEM, used for high-precision CNC machining parts, in the selection of process, will be based on the structure and technology of the parts, the function of the machine tool, the number of CNC machining content, etc. in addition, in addition to the principle of process concentration, we can also investigate the efficiency to select the principle of process dispersion, which all need to be determined according to the actual situation, and strive for high efficiency and efficiency Reasonable.

-

Related Reading

-

Features of precision milling aluminum CNC machining parts

2020-12-29

-

How to correctly use molds in aluminum die casting process

2020-12-24

-

The difference between CNC aluminum parts processing and mold processing

2020-12-24

-

How to extend the service time of CNC mechanical parts

2020-12-24