-

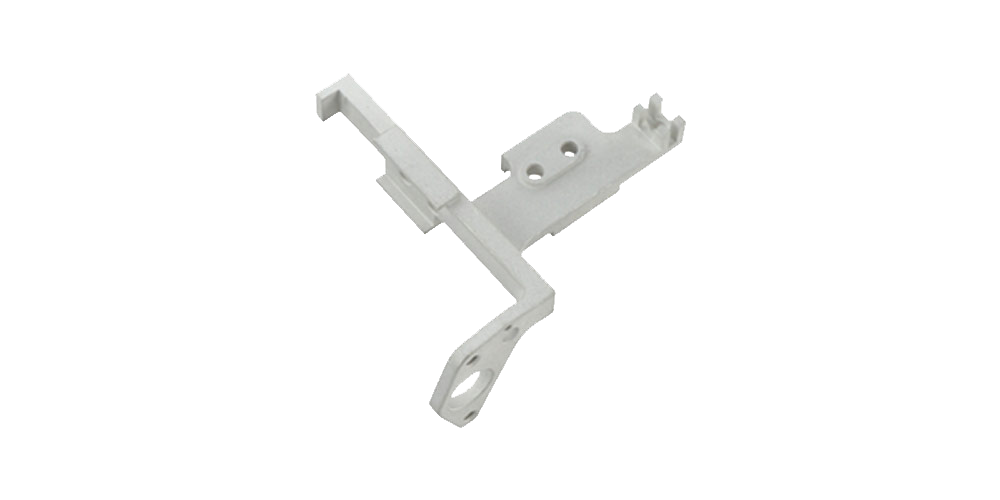

Stamping Parts

Stamping PartsProcessing Technic : CNC stamping,CNC milling,EDM,Punching,Drilling, Broaching ect.

Material Available: Aluminum/Stainless steel/Brass/Steel

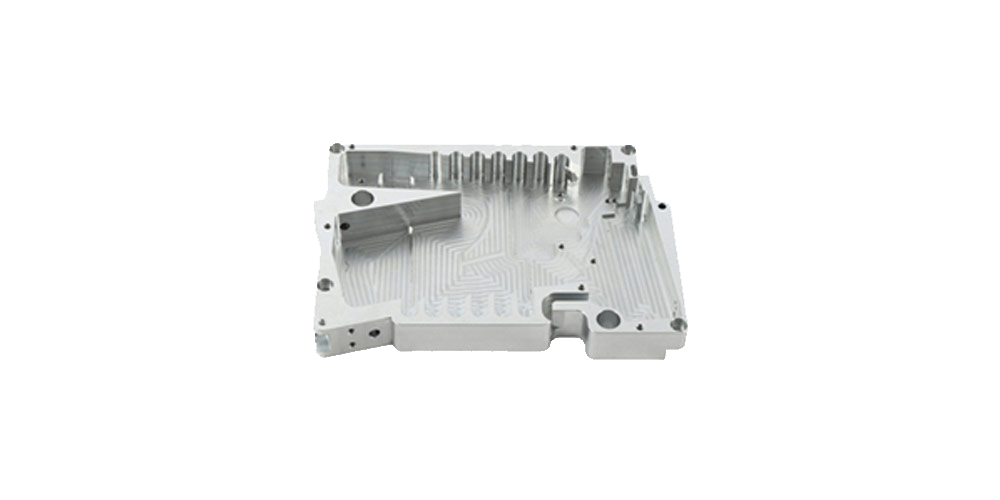

Die Casting

Die CastingProcessing Technic : CNC stamping,CNC milling,EDM,Punching,Drilling, Broaching ect.

Material Available: Aluminum/Stainless steel/Brass/Steel

stamping parts

stamping partsProcessing Technic : CNC stamping,CNC milling,EDM,Punching,Drilling, Broaching ect.

Material Available: Aluminum/Stainless steel/Brass/Steel

die-casting-parts

die-casting-partsProcessing Technic : CNC stamping,CNC milling,EDM,Punching,Drilling, Broaching ect.

Material Available: Aluminum/Stainless steel/Brass/Steel

aluminium die casting parts

aluminium die casting partsProcessing Technic : CNC stamping,CNC milling,EDM,Punching,Drilling, Broaching ect.

Material Available: Aluminum/Stainless steel/Brass/Steel

zinc die casting

zinc die castingProcessing Technic : CNC stamping,CNC milling,EDM,Punching,Drilling, Broaching ect.

Material Available: Aluminum/Stainless steel/Brass/Steel

China CNC turning parts supplier, manufacturer, factory

What is CNC machining parts service?

What is CNC machining parts service?CNC machining parts service is the abbreviation of CNC machine tools, which is an automatic machine tool equipped with a program control system.

The control system of CNC machining parts service can perform logical processing on the program with control code or other symbolic instructions, decode it, express it with code, and input it into the numerical control device through the information carrier. After arithmetic processing, the numerical control device sends out various control signals to control the action of the machine tool, and automatically process the parts according to the shape and size required by the drawing.

Technical application of CNC machining arts service:

CNC machining parts service is an automatic machine tool equipped with a program control system, which enables the machine tool to move and process parts in accordance with the programmed program. It integrates the latest technologies such as machinery, automation, computers, measurement and microelectronics, and uses a variety of sensors.

The sensors used in CNC machining parts services mainly include photoelectric encoders, linear gratings, proximity switches, temperature sensors, Hall sensors, current sensors, voltage sensors, pressure sensors, liquid level sensors, resolvers, induction synchronizers, speed sensors, etc.., mainly used to detect position, linear and angular displacement, speed, pressure, temperature, etc.

What is the difference between a CNC machine tool for CNC machining parts service and an ordinary machine tool?

The differences between CNC machine tools for CNC machining parts service and ordinary machine tools are as follows:

1. Different meaning

The spindle of an ordinary machine tool needs to be in the spindle box. The motor transmits torque through belts and gears with different transmission ratios to realize the processing of the workpiece.

The CNC machine tool for CNC machining parts service is a CNC machine tool, which is an automatic machine tool equipped with a program control system. The control system can perform logic processing on the program with control codes or other symbolic instructions, decode it, express it with coded numbers, and input it into the numerical control device through the information carrier. After arithmetic processing, the numerical control device sends out various control signals to control the action of the machine tool, and automatically process the parts according to the shape and size required by the drawing.

2. Different structure

Ordinary lathes adopt gear shifting, and the shifting handle needs to be turned to shift the speed. CNC machining parts service lathes generally use CNC programs to change the speed. Ordinary lathes use trapezoidal threaded screws to process the threads and cut them with polished rods. All CNC machining parts service lathes use ball screws. The tool post of ordinary lathes is generally on the operator's side, the tool post of CNC lathes is mostly on the opposite side of the operator, and the tool post of economical CNC lathes is on the operator's side.

The guide rails of ordinary lathes are hard rails, and the guide rails of CNC lathes have hard rails and linear guides. Ordinary lathes have large handlebars, middle handlebars, and small handlebars. CNC lathes do not have these handles, and there is no trolley frame.

3. Different operating efficiency

Ordinary lathes are driven by gears and ordinary lead screws and nuts. Due to the inaccuracy of the gap between the kinematic pairs and manual operation, the repeat accuracy is low. Normal lathes need to be manually measured after stopping the machine for measurement. The measurement error is large and the efficiency is low. It is suitable for small batches, low precision parts, and spare parts. Its investment is lower than that of CNC, but it requires higher operating skills for workers, so the wage level is higher. The scrap rate and productivity of low-level workers will give you a headache.

The CNC lathe for CNC machining parts service adopts a fully enclosed or semi-enclosed protection device. Use automatic chip removal device. The spindle speed is high, and the workpiece clamping is safe and reliable. The hydraulic chuck is adopted, which is convenient and reliable to adjust the clamping force, and also reduces the labor intensity of the operator. The tool can be changed automatically.

The CNC lathes for CNC machining parts service all adopt automatic rotary tool holders, which can automatically change tools during the machining process, and continuously complete multiple processes. The main drive and feed drive of the CNC lathe adopt independent servo motors, and the drive chain is simple and reliable. At the same time, each motor can move independently or realize multi-axis linkage.

CNC machining parts service has the following characteristics:

1. CNC machining parts service is highly adaptable to processing objects, adapts to the characteristics of single-piece production of molds and other products, and provides suitable processing methods for mold manufacturing;

2. CNC machining parts service has high machining accuracy and stable machining quality;

3. CNC machining parts service can carry out multi-coordinate linkage, and can process parts with complex shapes;

4. When machining parts are changed, generally only the NC program needs to be changed, which can save production preparation time;

5. The machine tool used for CNC machining parts has high precision and high rigidity, can choose a favorable processing amount, and has high productivity (generally 3 to 5 times that of ordinary machine tools);

6. The machine tool has a high degree of automation, which can reduce labor intensity;

7. Conducive to the modernization of production management. CNC machine tools use digital information and standard codes to process and transmit information, and computer control methods are used to lay the foundation for the integration of computer-aided design, manufacturing and management;

8. Higher requirements for the quality of operators and higher technical requirements for maintenance personnel;

9. High reliability.

Boyang is a leading China CNC turning parts factory that focuses on CNC turning parts. We focus on producing high-quality Boyang CNC turning parts with complete specifications.

Boyang CNC turning parts

When designing and developing new products according to customer needs, we strictly control quality standards while controlling production costs.

You can follow the link to see our facebook homepage.

Click on the link to go to our LinkedIn homepage.

You can also click the link below to enter our YouTube homepage to view.